In today’s fast-paced manufacturing environment, every second counts. With complex machinery, automated processes, and continuous production demands, manufacturers can’t afford to rely on outdated systems or inefficient processes. This is where PLC programmers come into play.

A PLC (Programmable Logic Controller) programmer plays a crucial role in the success of modern manufacturing operations. These professionals design, implement, and maintain the control systems that drive automation. Without them, manufacturing plants would struggle with inefficiencies, high error rates, and potentially even system breakdowns.

Let’s break down why PLC programmers are absolutely essential.

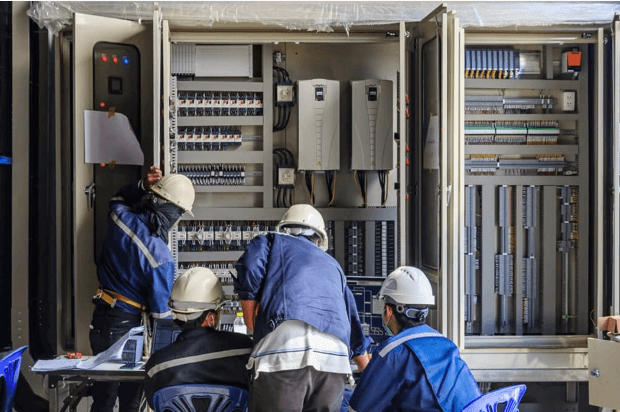

What Exactly Does a PLC Programmer Do?

A PLC programmer designs the programming that allows machines to operate automatically. These systems control everything from assembly lines to robotic arms, to packaging machines—anything that requires automated movement or action.

By writing the necessary code and developing systems, PLC programmers ensure that the machines and processes work smoothly. They make sure that sensors, actuators, and other components communicate properly, enabling a plant to function at peak efficiency.

In simpler terms, these programmers are responsible for making sure that machines do their job—consistently, safely, and reliably. It’s not as simple as just pushing a button. The systems they create or optimize are the backbone of a modern factory.

Why PLC Programmers Matter in Manufacturing

Optimizing Efficiency and Productivity

One of the most critical aspects of modern manufacturing is efficiency. Every minute of downtime or inefficiency costs money. PLC programmers develop systems that automate processes, reducing the need for human intervention. This not only speeds up production but also ensures greater accuracy and fewer errors.

For instance, imagine a PLC programmer optimizes the code behind an assembly line. Instead of workers manually adjusting machines or performing repetitive tasks, the PLC system ensures everything is automated, running faster and with fewer errors. This drastically improves both the speed and reliability of production.

Ensuring Safety and Reliability

Manufacturing environments can be hazardous. Machines running without proper oversight or automation can pose a significant risk to worker safety. PLC systems help mitigate these risks by automating control processes and monitoring machine performance in real-time.

In critical industries like aerospace, automotive, or food processing, where safety standards are non-negotiable, PLC programmers ensure that systems react instantly to potential faults or emergencies. Without PLC programmers to ensure proper safety protocols, manufacturing could become much riskier.

Reducing Operational Costs

By implementing automation through PLC programming, companies save money in various ways. Fewer manual tasks mean less labor, and more efficient machines often mean lower energy consumption.

But it’s not just about the immediate savings. Efficiently programmed PLC systems often extend the lifespan of machinery. Machines that run smoothly and with fewer errors tend to break down less frequently, resulting in less downtime and fewer maintenance costs.

In this way, PLC programmers are not just an expense—they’re a strategic investment in the long-term health of the business.

See also: Common Pitfalls That Derail TM44 Compliance and How to Avoid Them

How Do PLC Programmers Improve Manufacturing?

A PLC programmer’s job doesn’t end at programming the code. They are involved in almost every stage of the manufacturing process. Here’s how:

System Integration

Modern factories rely on various systems working together—conveyor belts, robotic arms, packing stations, and more. Each of these components needs to communicate with the others seamlessly. PLC programmers handle this integration, ensuring that all parts of the system work in harmony.

Real-Time Monitoring and Troubleshooting

A big part of a PLC programmer’s job is monitoring the system in real time. If something goes wrong—whether a machine malfunction or a software bug—the PLC programmer identifies and fixes it immediately. This is crucial to avoid downtime, which, in a manufacturing setting, can mean huge financial losses.

Customizing for Specific Needs

Every manufacturing plant has unique requirements. A PLC programmer tailors the system to meet those specific needs. They program machines for high-speed production, intricate assembly, or custom packaging solutions—whatever the business requires.

The Demand for PLC Programmers Is Growing

As the world of manufacturing continues to move toward automation and smart technology, the need for skilled PLC programmers is only increasing. Companies are looking for professionals who can design, maintain, and troubleshoot these complex systems.

In industries like automotive, aerospace, and food processing, automation is more than just a luxury; it’s a necessity. As global competition grows, companies need to keep up by optimizing their operations, which heavily relies on reliable control systems. And that’s where PLC programmers step in.

Without them, manufacturing plants would fall behind—not just in productivity but also in safety, quality control, and efficiency.

Final Thoughts

PLC programmers are the unsung heroes of modern manufacturing. They ensure that machines are running smoothly, that production lines are efficient, and that safety protocols are in place. Without them, the modern manufacturing landscape as we know it wouldn’t be possible.

Their role in improving productivity, reducing costs, and enhancing safety makes them essential to any manufacturing operation. If you’re considering a career in this field or looking to hire a PLC programmer for your business, the importance of their expertise cannot be overstated.